29/09/2022

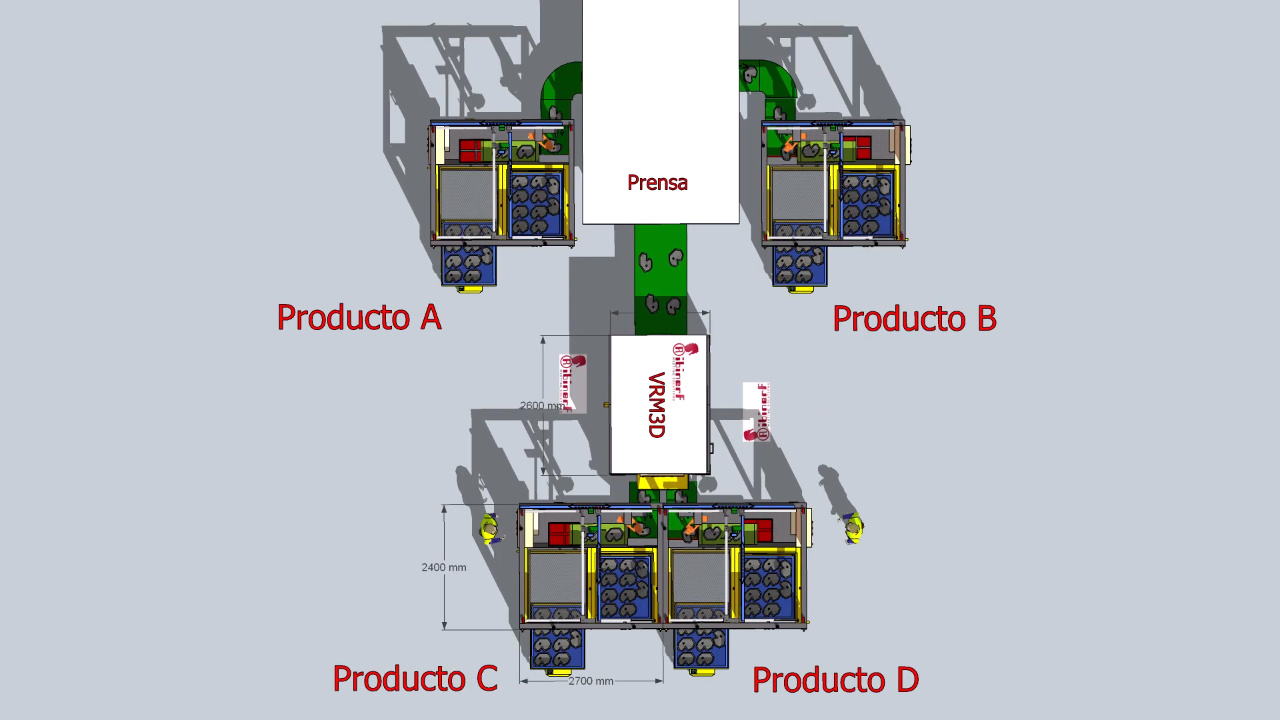

Self-programmable solution for stacking parts in containers at the press exit, automatically at 1800 parts/hour.

Our new CPM is a solution for the stacking of parts in containers at the exit of the press, without any tooling or format change. A compact, portable and modular machine, which allows to feed parts at a rate of up to 1800 parts/hour and with an Artificial Intelligence system that automatically programs itself and makes the mosaic in the container.

The parts arrive unpositioned via the conveyor at the exit of the press. The system identifies them with a 3D vision system, which makes it immune to differences in the color of the parts, oil, position, rotation, etc. This avoids the need for tooling for each model. The system stacks the parts inside the container.

The machine has been designed for those applications in which a large number of different formats are processed and the programming of the robot and the vision for each model is very costly. For this reason, an Artificial Intelligence has been designed which, by simply passing each piece with the machine empty, learns the model, searches for the viable picking point and even designs the stacking mosaic in the container. In this way, a format is programmed in just 5 minutes, which results in significant improvements in productivity and cost savings by avoiding the production stoppages that until now involved the programming of each new format.

The new CPM-SD is delivered with the commissioning done in the factory, like all our machines. It takes only 1 day to set up and is ready for production start-up; only minor adjustments are required during production. The machine is portable so it can be moved from one press to another if necessary.