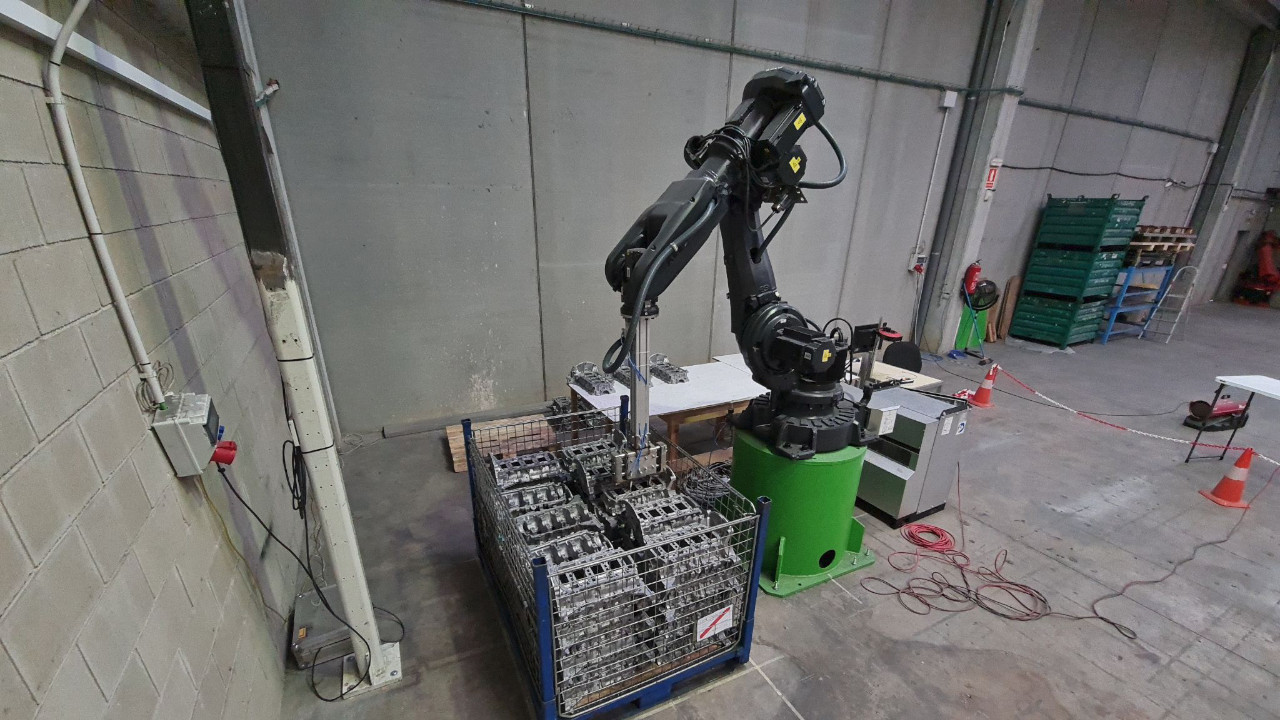

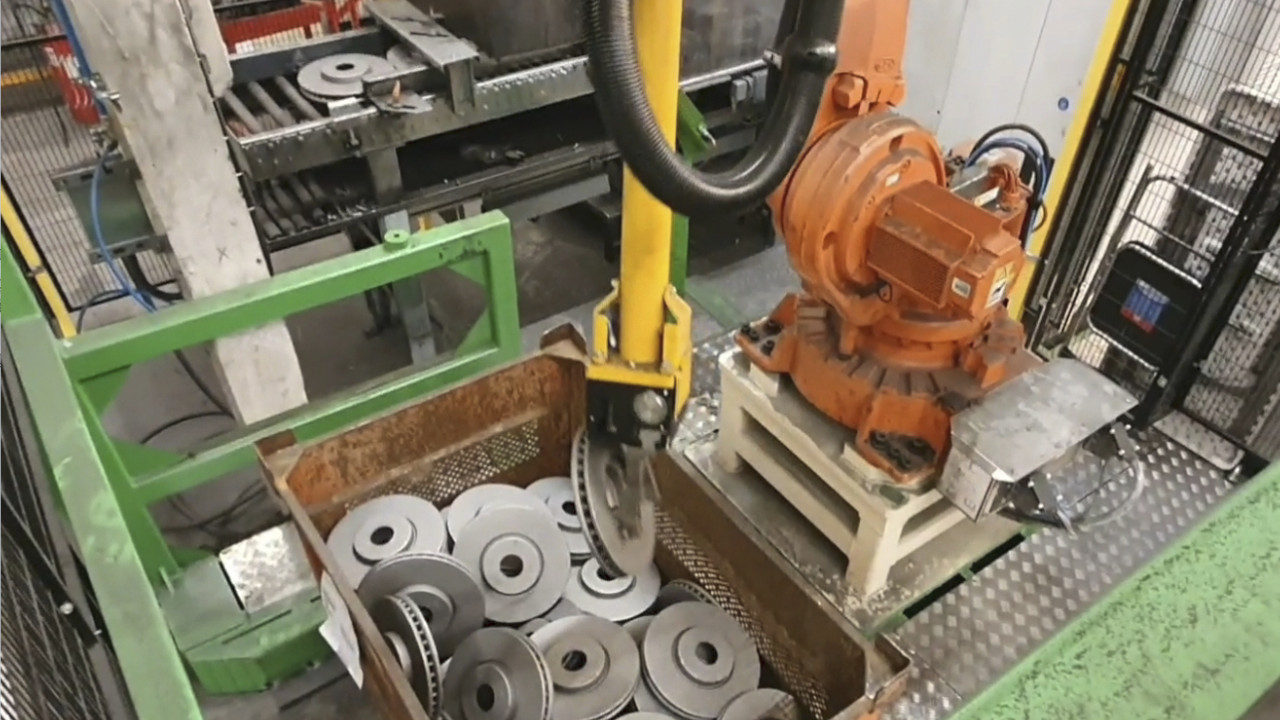

The Bin picking Portable Machine is an industrial automation solution that uses machine vision and robotics technology to accurately and efficiently identify and pick parts from a container.

Key requirements for efficient and safe production

- Generate a stable and smooth process of picking and positioning of parts to improve the quality of the final product and increase the efficiency of the production line.

- Automate a process with little added value and a cost factor in production.

- Reduce the need for direct labor, which can increase efficiency and reduce production costs.

- Cover labor shortages by freeing up workers for more complex and higher-value tasks.

- Reduce the risks of injuries and accidents, as well as improve working conditions in general, which can increase worker satisfaction and productivity.

Operation of the bin picking portable machine

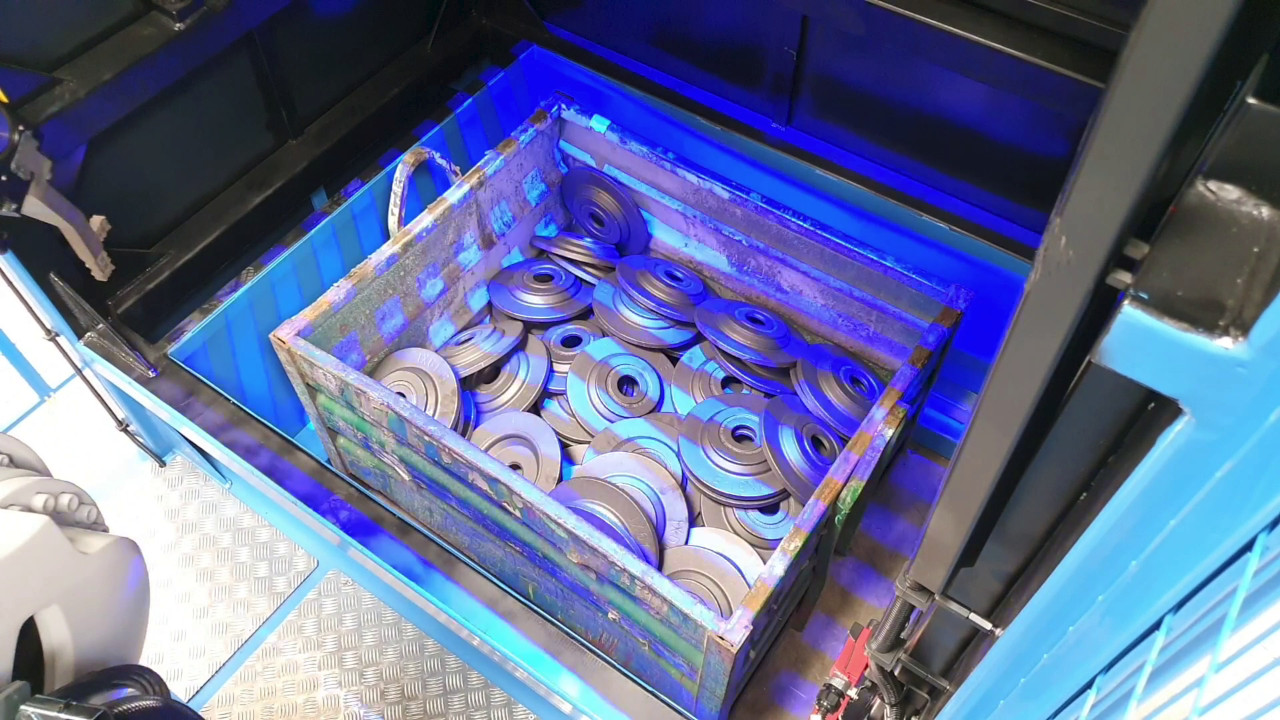

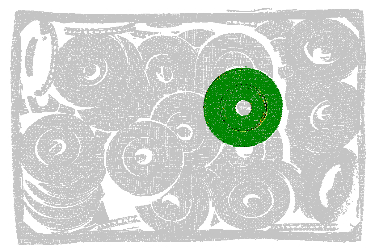

1.The scanner acquires a 3D point cloud of the container to locate the part and analyze any issues using Virtual Reality. The following actions are performed:

- Ensure that the part does not overlap with other parts in the container.

- Avoid collisions with other parts in the container.

- Control nested parts to avoid taking two parts at the same time.

- If the part is not the programmed model, it is left inside the container.

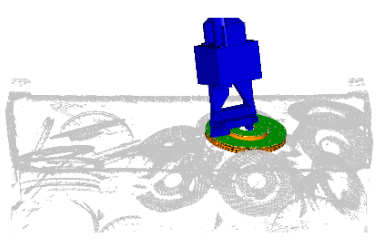

2.With the information from the scanner, the robot calculates all possible paths to pick up the part and selects the path where any obstacle or collision is avoided. In addition, it calculates the position of the grippers to safely extract the part from the container.

3.Once the part is picked up, the robot places it on the conveyor, CNC or process it feeds.

THE NON-STOP MACHINE

Thanks to our artificial intelligence (AI) software, our machine is able to solve alone the vast majority of incidents where other machines are stuck waiting for an operator, avoiding downtime and loss of production. Some examples of solutions offered are:

- Parts are hidden one under the other and the robot picks up two. The stress sensor detects it, drops the parts and picks up another one.

- Parts sideways, which are hardly visible but generate a collision. The stress sensor detects it, ignores the part and proceeds to pick up another one.

- Scenario in which there is no extractable part. The system stirs the parts to change the scenario until a extractable part appears.

- Pickup points at which the robot enters in singularity.

In each of these cases, our machine AI detects, analyzes and solves the problem autonomously without the need for human intervention. This reduces downtime, improves efficiency and maximizes production, resulting in cost savings and a competitive advantage in the marketplace.

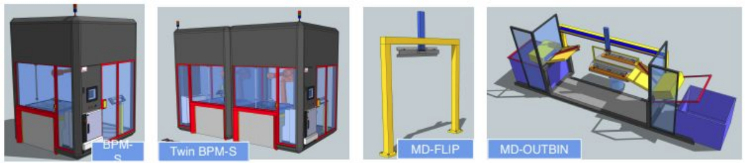

Modular technology to increase production efficiency

The solution is modular and scalable, so that several modules can work simultaneously, feeding a single machine in half the cycle time. A part turning device can be incorporated, which does not consume robot cycle time.

Standard part specifications

Additional features

The high-precision, motionless scanning system has been designed to adapt to different container sizes and ensure accurate location of the parts inside. In addition, it features automatic calibration between the scanner and the robot in the event of an incident, allowing quick troubleshooting in less than 2 minutes without the need for the presence of a specialized operator.

The machine is highly customizable and adaptable to different processes, allowing seamless integration with your production line. The machine is portable and can be installed in as little as one day, making it easy to implement and reducing downtime.

The return on investment (ROI) of such a machine is less than 2 years due to reduced direct labor and increased efficiency in picking and placing parts.

In addition, we offer complete training to operators so that they can perform maintenance and program the new models autonomously, allowing greater control and autonomy in the maintenance and operation of the machine.

Downloads

Bin picking Portable Machine Data sheet

Send download link to: