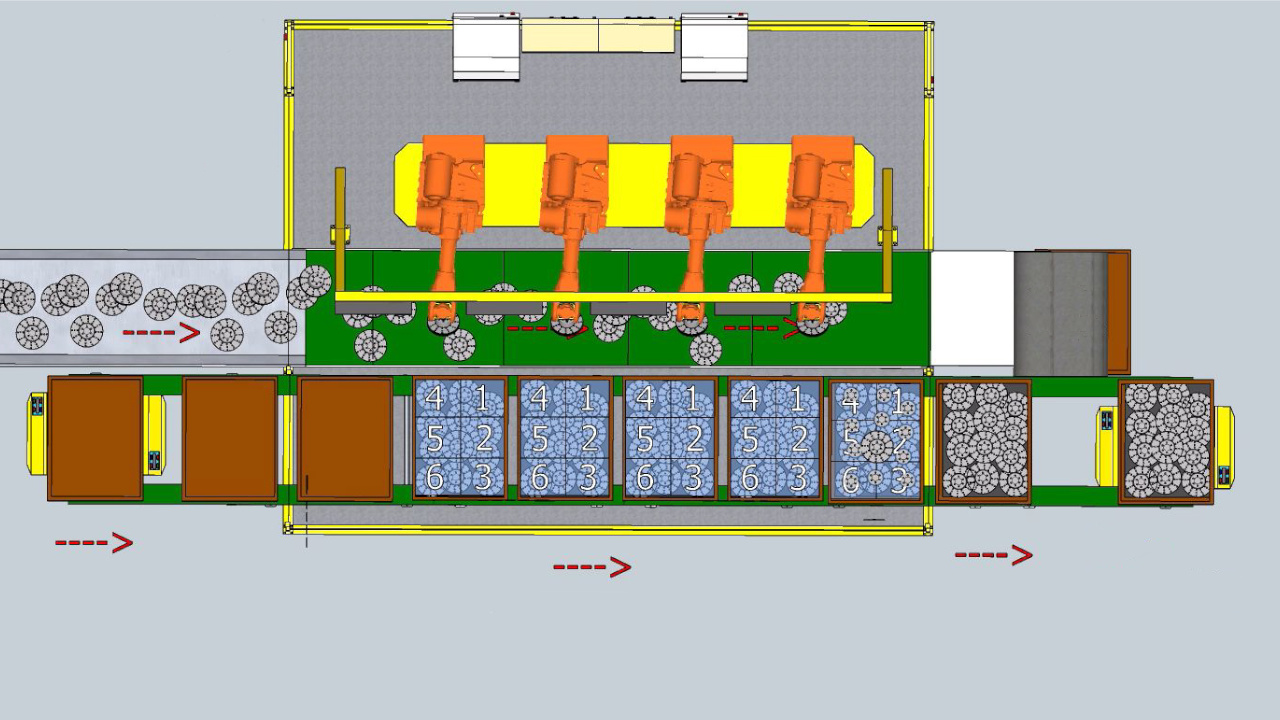

Our Containerizing Unmoulded Parts 3D system is modular and allows efficient sorting and separation of hot parts, scrap and sand from the demolding process. Using 3D scanners and robots, the parts are sorted into the corresponding containers or conveyor belts.

Key requirements for efficient and safe production

- Quickly sort and separate the hot parts, coming out of the demolding process, from the conveyor belt, mixed with sand and scrap, to take them to quality control, touch-up, etc.

- Allow the combination of different parts in a high-speed flow.

Operation of the Containerizing Unmoulded Parts 3D

1.The parts, together with casting waste and sand, arrive at the vibrator from the demolding process.

2.The vibrator separates the stacked parts and the flow moves continuously in a conveyor.

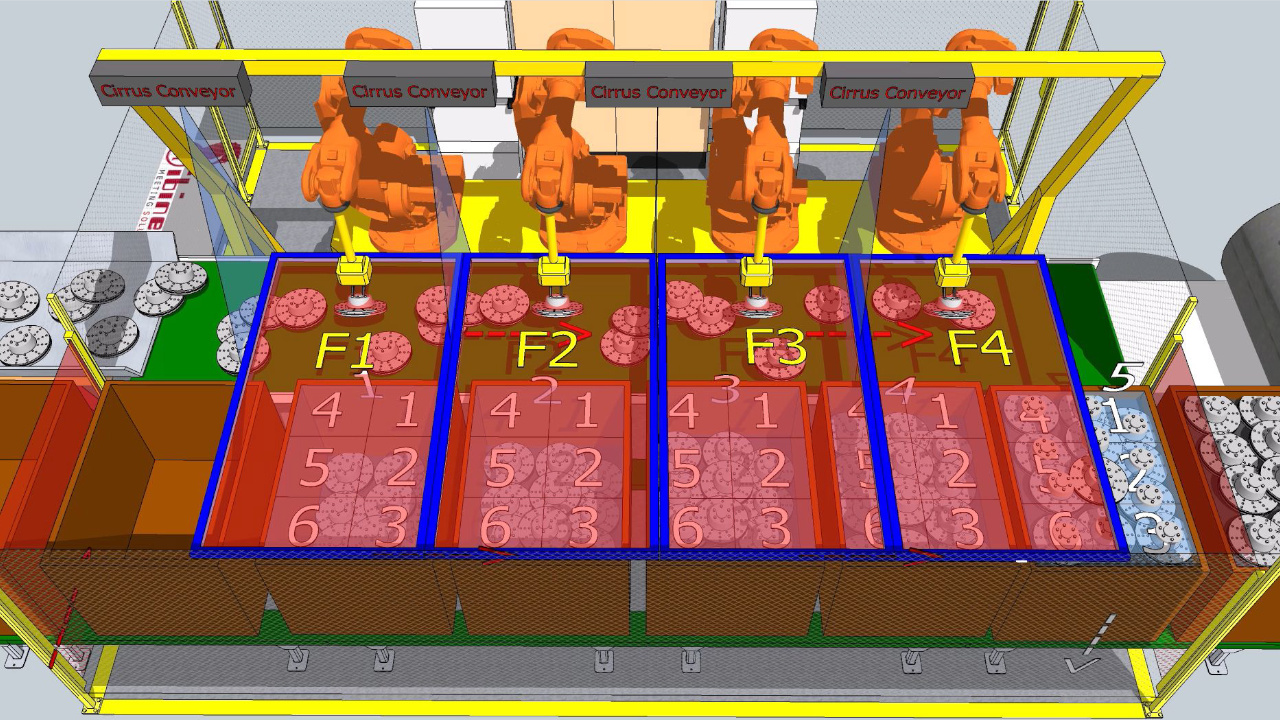

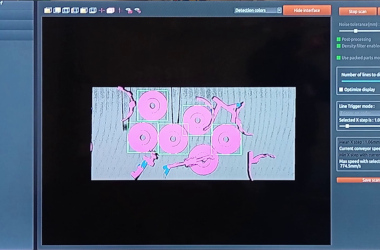

3.The flow of parts passes through picking zones equipped with 3D scanners and robots that identify and sort the parts into corresponding garbage cans. Each robot can identify and pick up parts of different formats and place them in one of the two containers.

4.The first robot picks up all possible parts of all models, the second robot picks up the parts not picked up by the first one, and so on. The number of robots depends on the production. The debris, sand and uncollected parts fall to the end, where a magnetic separator can be placed to separate the iron pieces and sand.

With 3 robots, production can reach up to 20 parts per minute.

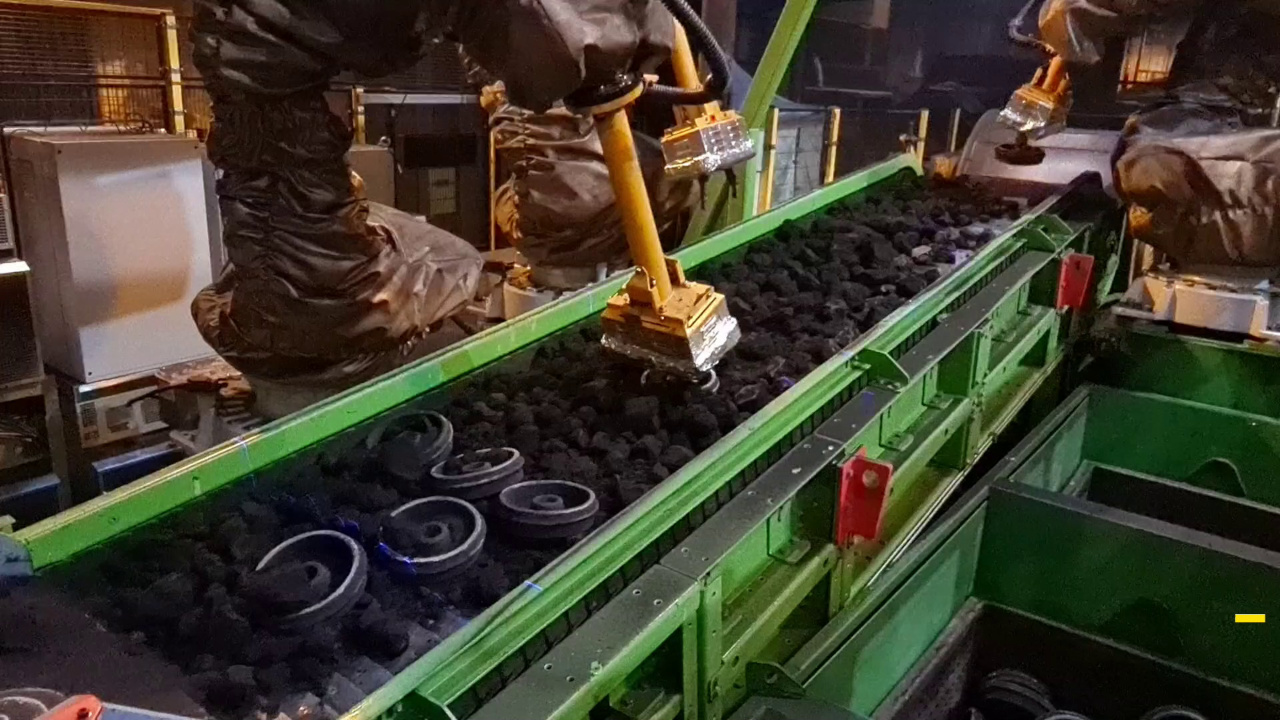

ROBUST SYSTEM FOR HARSH ENVIRONMENTS

The modular Containerizing Unmoulded Parts 3D system is designed to operate in a highly challenging environment, where parts can reach temperatures up to 700°C and ambient dust is common. In addition, it must be able to handle the mix of different types of parts in the same workflow. To ensure efficient and safe production under these conditions, specific protective measures have been implemented.

- A scanner housed in an air-flow cooled protective enclosure and protected by an additional heat shield on the outside.

- The claws are housed in an insulating box with an additional external heat shield.

WE KEEP PRODUCTION RUNNING WITH OUR AUTO RECOVERY SYSTEM

The system features a collision control that avoids crashes and system stoppages, allowing for more efficient production. Although the scanner locates parts and performs preventive collision control, sometimes a collision is unavoidable. The Auto Recovery system avoids system blockages and continues with the next part.

Additional features

- The modularity of the system allows the sorting of several mixed models, which increases production flexibility and adapts to the specific needs of each customer.

- The system modules are transportable and can be quickly connected, allowing for easy installation and commissioning.

- The mechanical and electrical assembly of the system can be performed in only 5 shifts, which significantly reduces installation time and minimizes downtime.

Downloads

Containerizing Unmoulded Parts 3D Data sheet

Send download link to: