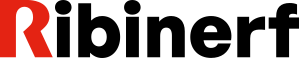

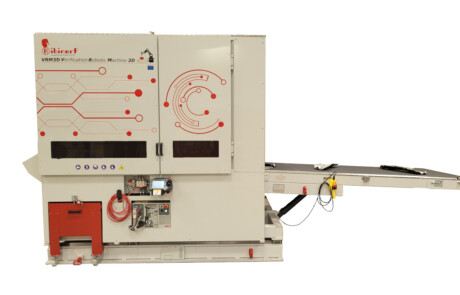

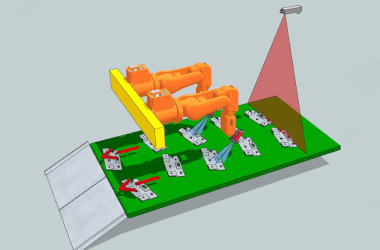

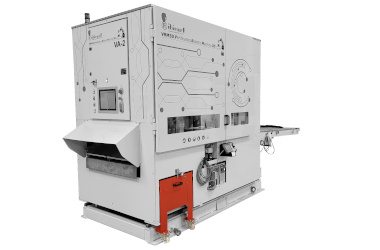

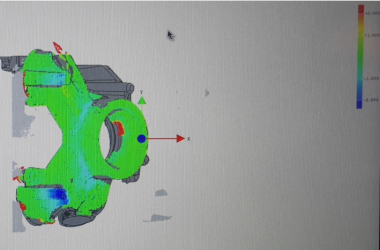

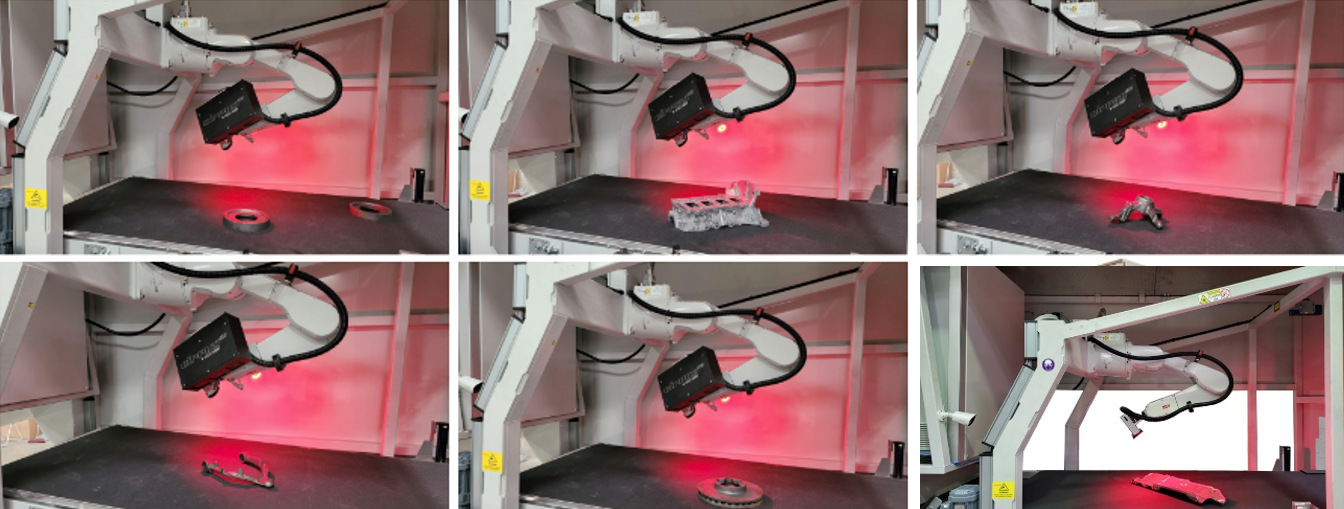

The 3D Robotic Verification Machine is a solution for the quality control of parts that uses a 3D point cloud of the scanned area to compare it with the theoretical model in search of non-matches. It compares the part with the CAD model, with a resolution and repeatability of 0.1mm, allowing to increase the production of the next process by eliminating defective parts.

Key requirements for efficient and safe production

- Detect defects on in-line parts during the manufacturing process to ensure that required quality standards are met.

- Identify the type of defect detected in order to perform actions in the manufacturing process.

- Monitor production in real time to detect potential problems and avoid production line stoppages.

Operation of the Verification Robotic Machine 3D in 5 steps

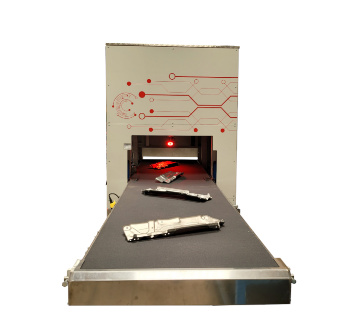

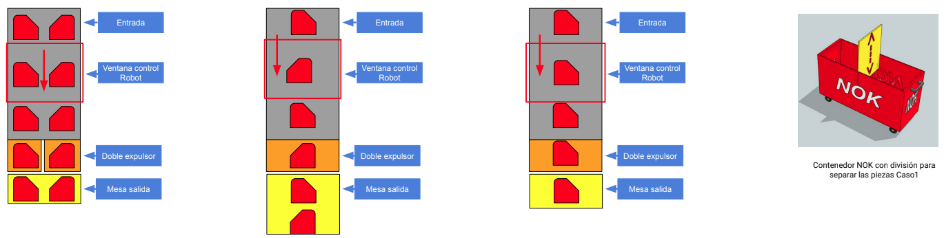

1.Entry of the part with the control side facing up, regardless of its position or rotation.

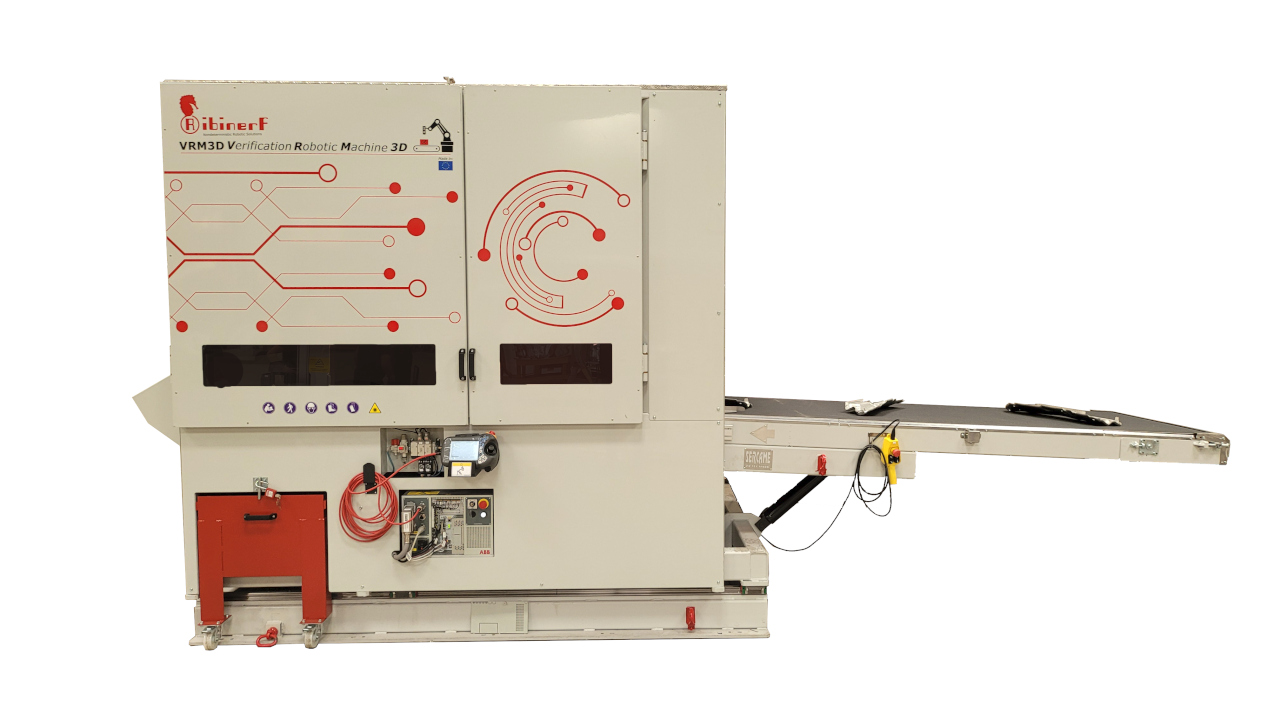

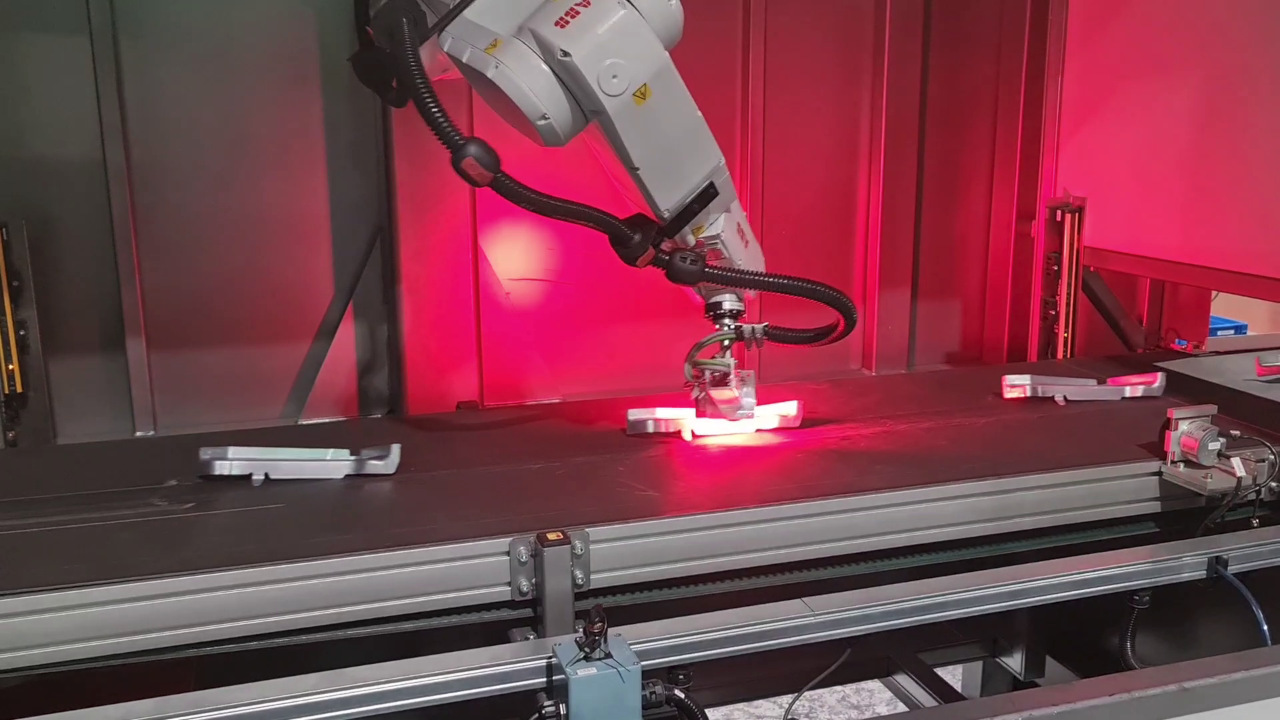

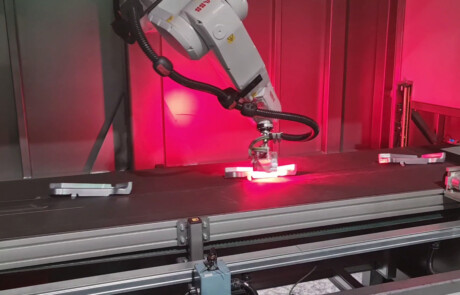

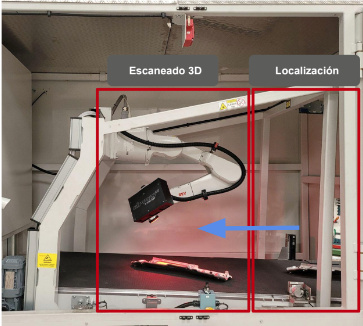

2.Scanning the part with the 3D scanner to locate it and perform an overall quality control of the part. The scanner also repositions the robot.

3.The robot positions the head in all programmed views of the part to compare with the CAD model, allowing control of defects that can only be seen in relief and are not affected by stains or colors that do not have relief.

- It detects presence or absence of dies, nuts, inserts, small cracks, marks, bumps, deformations, open folds, burrs and can also read codes and verify logos.

- It is immune to color changes in the part, rust or surface stains, color changes in the sheet metal, presence of oil coating and superficial marks.

This is done without tooling and in high production.

4.Finally, the NOK parts are rejected into an integrated red drawer while the OK parts are allowed to pass.

5.The system stores the results of each part and the images of the NOK controls in a SQL Server Express database, either locally or remotely. In addition, it has a web server that allows access to the pages with the results from a web browser. From the same browser, it is possible to print or save in PDF format the results obtained.

Request a Personalized Demonstration Today

Discover the Future of Parts Quality Control with VRM3D

Would you like to discover how our VRM3D can transform your parts quality control operations? We invite you to explore the power and precision of VRM3D through our exclusive demonstrator. This is your opportunity to experience firsthand how our technology can adapt to your specific needs and improve your verification processes.

What Does Our VRM3D Demonstrator Offer?

- Customized Testing: We conduct tests with your own parts, demonstrating the effectiveness and precision of VRM3D in real-world scenarios.

- Expert Advice: Our team of specialists will be available to answer all your questions and show you how VRM3D adapts to your requirements.

- Immersive Experience: Live the VRM3D experience in action and see how our technology can optimize your processes.

How Can You Access the Demo?

It’s simple. Just send us a message through the following link or form, indicating your interest in the VRM3D demonstrator. Our team will contact you to coordinate a personalized demonstration that fits your schedule.

Don’t miss the opportunity to be at the forefront of robotic verification. Contact us today and take the first step towards the digital transformation of your parts quality control processes with VRM3D.

AUTOMATION AT YOUR FINGERTIPS WITH THE MACHINE THAT PROGRAMS ITSELF

Our AIP (Intelligent Programming Assistant) is an excellent solution for customers with many different models, as it significantly reduces the time and cost of programming, as well as drastically reducing the level of expertise of the customer’s personnel. In addition, the system’s continuous automatic learning improves accuracy and efficiency over time, making it a scalable and cost-effective solution for industrial process automation.

The 3D Robotic Verification Machine programs itself thanks to an intelligent system that automatically learns each part format with the help of a person who will simply apply the next steps:

- Place the new part model at the input of the input conveyor so that the system learns the part shape.

- Indicate on the screen the regions of interest (ROI) that you want to check on the part.

- Pass several OK and NOK parts so that the system learns the variability of the parts within the ROIs, and therefore learns to distinguish between good and bad parts.

Find the perfect solution for your production

The 3D Verification Robotic Machine is a perfect solution for production processes that require detailed analysis of parts at different stages. The machine can analyze up to 30 parts/minute and helps to increase the throughput of the next process by eliminating NOK parts.

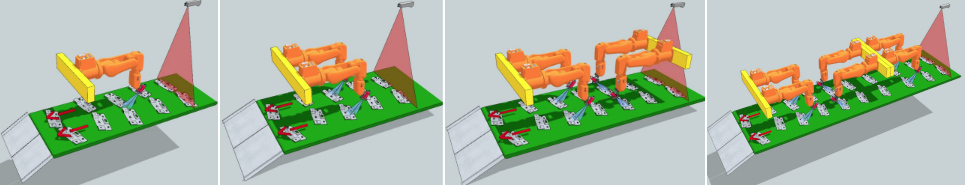

In particular, its ability to adapt to different production needs, such as double hand parts entry, where two hands of parts enter side by side, or for double pattern parts, where two hands of parts enter, but one behind the other, makes it very versatile and suitable for different types of production.

In addition, the 3D Verification Robotic Machine is a modular solution that adapts to various needs, such as:

- Increase production.

- Add more control points of the part.

- When a single robot is not sufficient to cover the entire width of the conveyor, it can be done with several robots, which share the work.

- Deal with large parts between several robots that share the work.

Depending on the production objectives, it is possible to build multiple scenarios using more or less robots, considering that the time per point and robot remains around 1 second per point.

Additional features

- The 3D Verification Robotic Machine is available in two configurations:

- Basic model: designed to be integrated into an existing pallet line and does not include conveyor, repositioning scanner or ejector.

- Complete model: includes conveyor, infeed location scanner, ejector, etc. for processing loose parts without centering pallet.

- Instant part changeover for processing multiple formats per day, with no format changeover time.

- Self-programming, which allows new parts to be added with minimal downtime and with non-technical personnel.

- No part tools. Eliminates costs for adding parts and part changeover time.

- 4G remote communication with after-sales service for remote programming and technical assistance.

- Automatic generation of results reports sent by e-mail.

- The 3D Verification Robotic Machine is portable and transportable using a fork-lift or bridge crane, and does not require fixing if there is no risk of collision, allowing it to be relocated quickly and easily.

Downloads

Verification Robotic Machine 3D Data sheet

Send download link to: