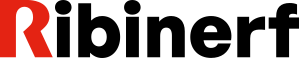

The Racking Machine is an industrial automation solution that efficiently places the parts coming from the press output into the container or rack using robots and a conveyor belt. This process is performed using a modular system capable of picking up the stamping parts in motion, either individually or stacked.

Key requirements for efficient and safe production

- Implement automated systems that allow parts to be handled quickly and accurately.

- Ensure safety in the production process to protect workers from potential risks associated with handling parts.

- Ability to adapt to different types of parts and production models to improve the efficiency and profitability of the production process.

- Ability to work with deformed racks and containers, and production variability, avoiding stoppages.

- Minimize errors in the handling of parts to improve the quality of the final product.

Operation of theRacking Machine in 3 steps

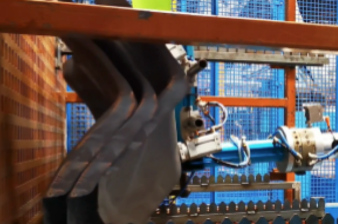

1.Parts pick-up: The modular system picks up the stamping parts in motion from the conveyor belt at the exit of the press, be it an individual part or a stack of parts.

2.Location and positioning: The system locates the position of the drop-off point and uses a gripper to place the parts inside the container/rack in an optimal position to avoid deformation of the racks or possible displacement of the stacks of parts during stacking.

3.Turning and stacking: If necessary, the system can turn the parts to better fit the container/rack and stack them neatly in vertical columns.

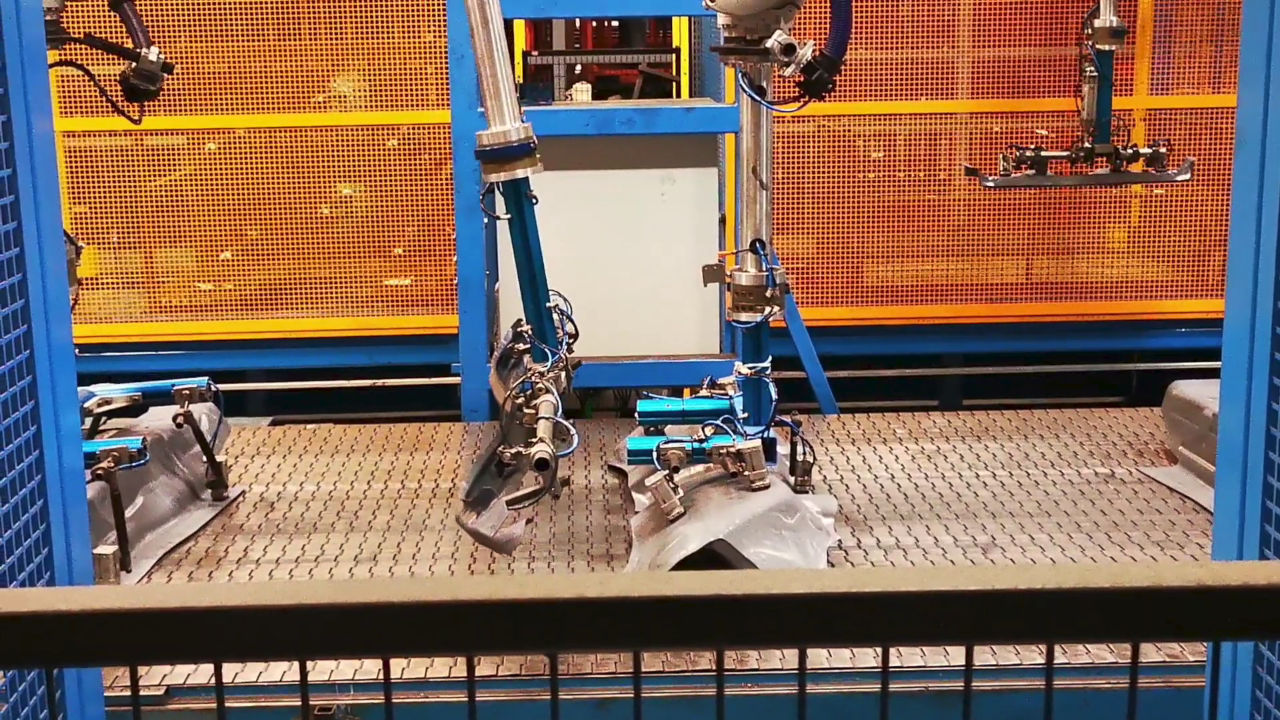

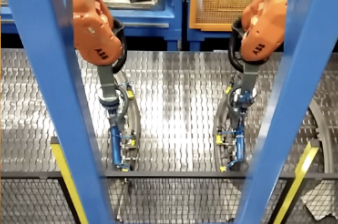

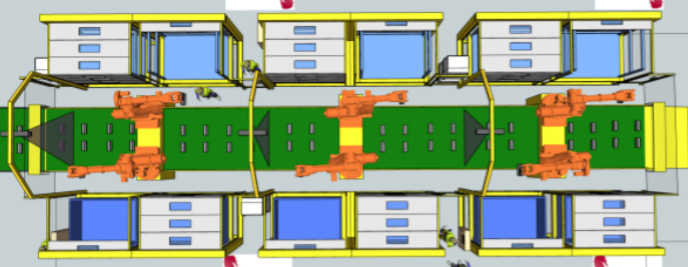

A MODULAR ROBOT SYSTEM

This system is equipped with robots that can pick up the parts quickly, taking between 8 to 10 seconds on average per robot. The solution allows modules to be added one after the other, which makes it possible to pick up different parts or two-handed parts and increases the production per part. In addition, the double output allows working without production stoppages and the symmetrical layout guarantees the same cycle time for each container without penalizing one or the other.

To ensure that all parts are positioned correctly, special grippers are incorporated to flip parts that require it. n the event that it is not possible to flip the parts with a single gripper, the two robots in the module work together to flip the parts and ensure that all parts are properly positioned.

In addition, the modules are designed to be transportable, reducing system installation and set-up time. The system can handle either a single part or a stack of parts, allowing for higher throughput with fewer modules.

This modular system has proven to be highly efficient and safe, allowing stamping parts to be placed quickly and accurately inside the corresponding container or rack.

RDRSS Racking DoubleRobot SingleSide

AutoPacking ML Model

Stamp Racking Hot stamping parts XL

Additional features

- Integrated scanner: The system has a scanner that allows locating the position of the anchor points in the container and the positions in which the parts are stacked, which facilitates management and reduces errors.

- Model flexibility: The system can be programmed to handle different part models, as well as vertical or horizontal stacking, allowing for greater production flexibility.

- Flipping capability: The ability to flip parts to better fit the container/rack is a useful feature to optimize storage space.

- Parts: Cold stamped or hot stamped parts.

- Modularity: The modular system is scalable, allowing production capacity to be expanded as needed.

- Return on investment: in less than 2 years