Ribinerf specializes in the automation of industrial processes. For more than 30 years we have been offering standardized and proven solutions to our customers. Our machines are capable of handling large and heavy parts, such as cast, forged or deep-drawn iron or aluminum parts, and work in aggressive environments such as foundries or stamping shops.

We offer specialized solutions for the automation of industrial processes, with standardized and tested machines to guarantee quality and efficiency in production.

Foundry

In the foundry sector, we offer standardized machines for the automation of loading and unloading processes, sorting and production verification.

Some of the parts for which we offer solutions:

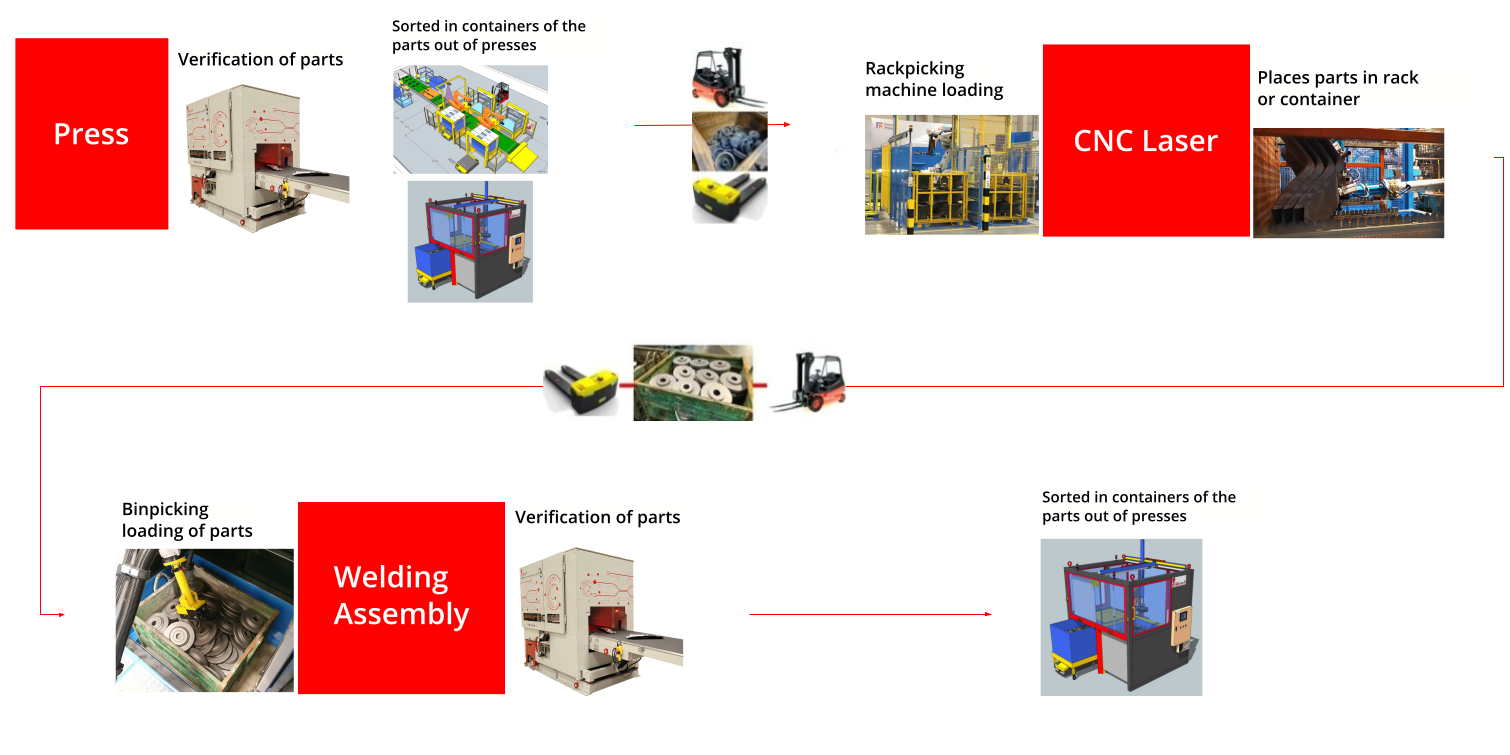

Stamping

In the stamping shop, our containerizing machines allow us to stack deep-drawn parts or flat blanks into containers without stopping the press to change the packaging. We also have a highly detailed 3D and 2D quality control machine that identifies parts that do not meet the required standards. We complete the automation of the process with unloading solutions such as rack picking, containerization or bin picking.